Polycarbonate Sheets - Common Questions Answered

Polycarbonate Sheets – Your Questions Answered

As one of the UK’s largest suppliers of multiwall polycarbonate roofing sheets and solid polycarbonate sheets we often get asked practical and technical questions about our products. Here we will try to answer the most common questions to hopefully help you choose the polycarbonate for your project.

Which is better PVC or polycarbonate roofing?

Generally, polycarbonate is a better material for roofing projects. Polycarbonate tends to be longer lasting, stronger and easier to work with. Having said that PVC roofing sheets are certainly not a bad choice. Corrugated PVC sheets are a cheaper material to purchase and modern PVC is UV protected to avoid brittleness making it a great choice for roofing. Corrugated PVC sheets also have a better light transmission than twinwall polycarbonate as they are a single skin and fitting corrugated roofing sheets can be an easier job than fitting polycarbonate as there are no glazing bars involved. However, from our experience of supplying both polycarbonate and PVC roofing sheets for many years in the UK polycarbonate is worth the extra cost over PVC as the benefit of insulation, lifespan and strength is a key deciding factor for most customers.

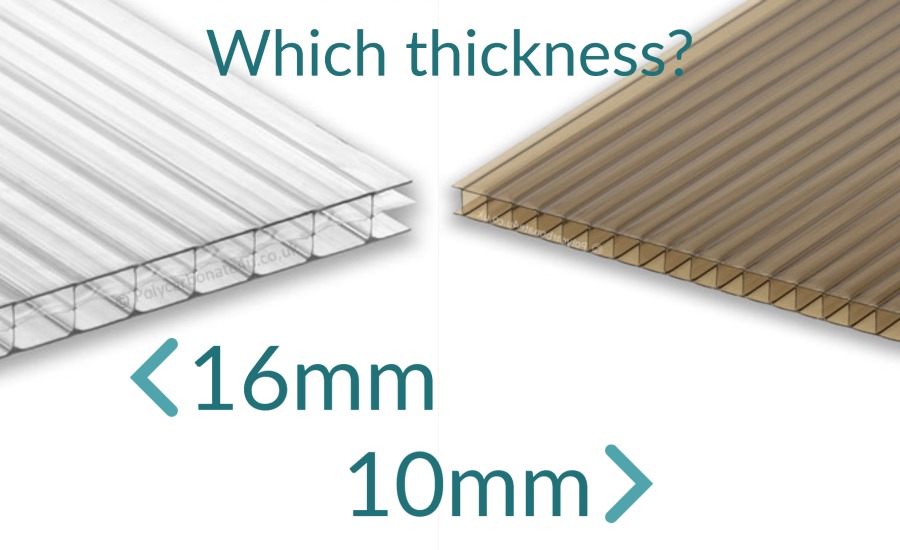

What thickness polycarbonate should I use for roof?

This depends on several factors. Firstly, you should ask yourself what you want from your roof? Do you need to retain heat in your conservatory, summer room or shed? Or is your main objective to provide shelter for an outdoor seating area, canopy or pergola?

In basic terms the thicker the polycarbonate roofing sheets the more insulation it will provide. This means if you are constructing a roof that is open on all sides using a thicker sheet such as 25mm or 35mm could be seen as wasteful as you will not reap the reward from the insulation value. Likewise using a 10mm sheet on a conservatory roof where you want to keep heated would not be a wise move.

As a general guide 10mm sheets are used for pergolas, canopies and carports using rafter supported glazing bars on a timber frame. 16mm polycarbonate sheets are mostly used for basic conservatories lean to’s, smoking shelters and walkways. 25mm and 35mm sheets are the more ‘premium’ sheets which are mainly used in conservatories, koi pond covers and high roofing applications. 16mm, 25mm and 35mm sheets can also be used with self support glazing bars which do not require a frame underneath.

In summary there is no right or wrong when selecting which sheet to use for you roof as there is a sheet for every project. Our team of advisors are on hand should you need help selecting the perfect sheet for you project – just contact us or click the ‘HELP’ button below.

What are the disadvantages of polycarbonate sheets?

The benefits of polycarbonate sheets far outweigh the disadvantages. The main disadvantage of fluted polycarbonate roofing sheets is the noise you get from rain. As sheets are effectively hollow rain noise can be exaggerated and gives a drumming sound in heavy showers.

Both fluted sheets and solid sheets are also susceptible to fine scratches – normally due to improper cleaning. On fluted sheets scratches are not normally visible but on solid sheets can be very noticeable. It is important to follow good cleaning techniques and not use any harsh chemicals on polycarbonate. Polycarbonate sheets should only ever be cleaned using warm soapy water.

How long does polycarbonate roofing last?

It will largely depend on where the sheets are going to be used. Firstly, it is important to recognise that all our polycarbonate sheets – both fluted and solid – are supplied with a manufacturers ten-year limited warranty. However we would expect sheets to last way beyond this if fitted correctly and maintained in accordance with the manufacturers guidelines.

Modern sheets should not yellow or become embrittled nor puncture in normal weather conditions. Sheets should always be installed in the correct manner to avoid premature ageing – following manufacturer’s instructions and maintained regularly. If this is carried out we would expect most sheets to last between 10 and 20 years.

How do you attach polycarbonate roofing sheets?

There are two ways in which polycarbonate roofing sheets are installed. For roofs constructed from timber the sheets are fitted using rafter supported glazing bars whereby a two-piece glazing bar is installed atop of your timber rafter which clamps the polycarbonate on the edge of the sheets. When you reach your final rafter an F-Section is used to terminate the roof and hide the joint beneath the polycarbonate sheet and the final rafter.

For roofs where no timber is going to be used then a self supported roofing system should be used. Self support glazing bars do not require a timber beneath and only need to be supported at the top and bottom of the bar. These systems lend themselves to better to conservatory roofs and like the rafter supported system are a join the sheets together using a snap down top cap. For the end rafters an edge bar should be used.

Is polycarbonate roofing noisy in rain?

Fluted polycarbonate roofing sheets are fairly noisy when compared to a glass roof when it rains. This is because the sheets are hollow so magnify the sound of the drops hitting the surface of the sheet. Solid polycarbonate sheets do not suffer with this as they are a dense solid material.

How do you walk on a polycarbonate roof?

We do not recommend walking directly on polycarbonate sheets under any circumstances. Whilst sheets are incredibly strong they remain flexible so if stood upon can bend. If sheets bend enough they can ‘pop out’ of the glazing bars meaning you will fall through the roof.

Should you need to get on top of your polycarbonate roof this should be done with the use of a crawl board to spread the load of your weight across multiple bars and sheets. We recommend only doing this when absolutely necessary.

Does polycarbonate roofing turn yellow?

Modern polycarbonate sheets are UV protected to prevent yellowing. Many years ago, when polycarbonate was first produced sheets were supplied without adequate UV protection. This led to a lot of sheets prematurely ageing, becoming yellow and leading to breakage from heavy rain. Modern sheets by comparison are far more advanced in this field. All of our polycarbonate roofing sheets are supplied with UV protection co-extruded into one side of the sheet. This means that sheets will withstand the harmful UV of sunlight and last for years to come. It is important with these sheets to ensure the UV protection layer is facing outwards / upwards upon installation – generally this is highlighted in writing on the protective film of the sheet. However once the protective film is removed it impossible to know for sure which side is up and which is down so be careful during the installation process!

All of our solid polycarbonate sheets are 2UV meaning they are UV protected on both sides. This means they are suitable for use outdoors and can be used either way around.

What should you not use on polycarbonate?

Harsh abrasive chemicals and cleaners should not be used on polycarbonate sheets. Polycarbonate is a thermoplastic which can be badly affected by non-approved chemicals. The only product we recommend for cleaning polycarbonate is warm soapy water and the only silicone that should be used is low modulus neutral cure that is specifically ‘suitable for polycarbonate’

Hopefully in this guide we have answered some of the most common questions however our experienced, knowledgeable team is on hand to answer any other questions you might have. You can contact us for a call back or click the ‘HELP’ button below for or assistance.